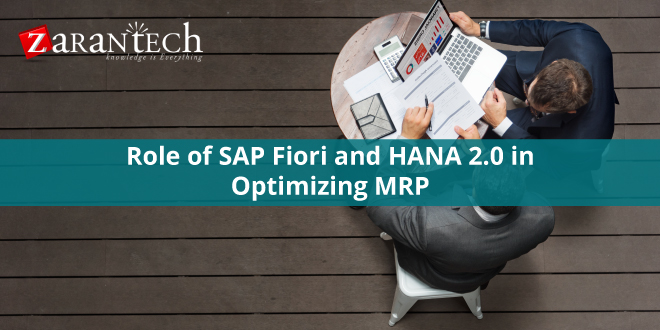

Role of SAP Fiori and HANA 2.0 in Optimizing MRP

Category: SAP FIORI & UI5 Posted:Nov 07, 2017 By: Serena Josh

A manufacturing enterprise takes massive starting capital and involves high risk as compared to service based industries like software companies. But with rapid advances in technology, certain factors such as quicker response times and connectivity are fast becoming essential for success as a manufacturing enterprise. Accurate and real-time information are also needed for the project planner for enterprise level planning. With various Key Performance Indicators (KPI’s) used for manufacturing units, the information flow should be optimized by the project planner to achieve most KPI’s. Checking inventory turnover, cycle time and no stock out positions are all key to enhancing enterprise productivity.

Traditional MRP vs. MRP Live

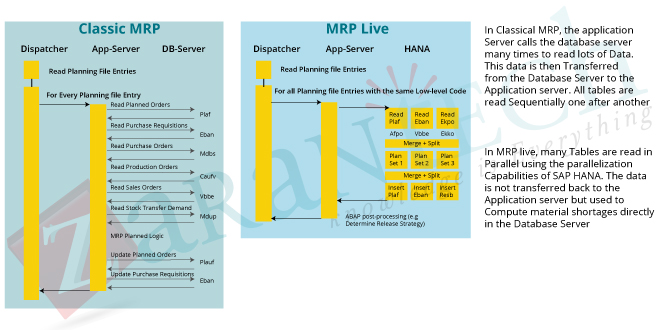

This brings us to comparing traditional Manufacturing Resource Planning (MRP) with what is available today. Conventionally planners would not be able to execute MRP periodically and with consistency, which would lead to bottlenecks in the enterprise. This means manufacturing units having massive data sets needing to be processed will be a great challenge. Such high volumes of unprocessed data will lead to high inventory volumes, misplaced or missing parts which in the end will drive up manufacturing costs. SAP S/4HANA comes to the rescue here, with its in-memory capabilities that accelerate MRP by as much as 10 times when contrasted with conventional MRP.

Conventional MRP has the system making multiple calls to the database server to get data from 52 different tables. All this data is read sequentially which backs up the process results. But when it comes to MRP live using SAP S/4HANA, the needs of various materials are read in parallel. The way this works is when MRP is run, data from various tables is read and transformed into a common structure while skipping irrelevant data tables. The calculations associated with shortages, needs, all are executed on the database server, thus creating the planned and purchase requisitions. HANA database capability helps eliminate the bottlenecks we spoke of earlier.

It is worth considering some of the additional advantages of MRP live which are as follows:

- The ability to plan multiple plants

- Planning a set of materials, elements and filtering it based on the individual in charge of a material across various plants

- MRP live automatically decides material planning sequence across different plants

- MRP live is a pre-requisite for the future production planning for PP/DS in SAP S/4HANA

Transforming Planning Approaches

The working approach for planners has been re-invented through the new user experience made possible by SAP Fiori and SAP HANA 2. With this the planner’s time is freed up to devote more attention to exceptions within processes and scenarios needing more attention for resolution, which includes financials. Fiori brings with it embedded analytical capabilities helping planners make faster and smarter decisions. SAP S/4HANA has its real time information shown across several areas such as lot sizes, stocks, availability procurement lead time, manufacturing schedules and sales orders across multiple locations.

Also system proposed solutions for shortages are shown through solution cards. The solution card provides information whether to reschedule purchases, raise volumes in a purchase order or to use stock transfers. The planners can make use of this information to check risks and their impact in real time and use this information to take corrective action.

There is real-time information and optimization logic in SAP S/4HANA which enables the planner to obtain the optimal replenishment parameters and strategies. The ability of such a system to contrast efficiencies of external and in-house replenishing at target sites is of great use, too say the least. This will clearly reflect in the balance sheets of the organization in terms of increased revenue in a relatively short period.

Some MRP-related FIORI apps are Monitor Material Shortages Monitor External requirements, Check material coverage, Monitor Material coverage like Net segments, Display MRP material issues Schedule MRP run Monitor Process Orders Monitor Production Orders, Monitor Internal requirements and a whole lot more.

A customer desirous of using both MRP live and traditional MRP can use the MD01N transaction code. The MRP run will see the system planning materials in accordance with low-level codes which are in turn decided by the Bill of Materials (BOM) that are maintained.

Where the system takes the low-level codes at first and executes material planning considered for MRP Live and traditional MRP. Secondly the system looks for materials with issues which cannot actually be planned by MRP Live. Post the first level code planning, it then goes for the remaining lower level codes. There are reports available to direct material planning to be done by the traditional MRP.

Conclusion

It is clear from the ways SAP Fiori and HANA 2.0 add to the optimization of MRP that enterprises should not neglect the importance of SAP Fiori and HANA. In future SAP comes up with innovative Fiori and HANA 2.0 adds on for effective optimization of MRP.

I hope that by now you have had an overview of SAP FIORI. Before you enroll in ZaranTech’s certification course on SAP FIORI &UI5, do check out the SAP UI5 and FIORI Tutorial for Beginners:

99999999 (Toll Free)

99999999 (Toll Free)  +91 9999999

+91 9999999