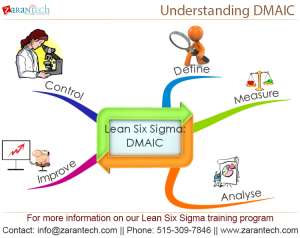

Understanding DMAIC

Category: General Posted:Jul 05, 2015 By: Alvera Anto DMAIC in Lean Six Sigma technique is also a management system that will result in refined, efficient projects. The Lean Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) method is the roadmap for problem solving. This methodology helps in product/process improvement. Most of the organizations begin implementing Six Sigma using the DMAIC methodology.

DMAIC in Lean Six Sigma technique is also a management system that will result in refined, efficient projects. The Lean Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) method is the roadmap for problem solving. This methodology helps in product/process improvement. Most of the organizations begin implementing Six Sigma using the DMAIC methodology.

DMAIC method is an iterative process that gives structure and guidance for the project and helps the analyst to focus on the improvement areas for the project. Now, Let us understand the DMAIC process:

Define Phase:

Define phase is the first phase of Lean Six Sigma process. This phase defines the efforts for the organization and defines the problems and critical areas for improvement.

Measure Phase:

Measurement is the most critical focus for the team to work on data collection. It helps to determine the start and end of the process to understand the root cause for the problem.

Analyze Phase:

This phase is combined with the measure phase. Since the team collects the data for analysis. They also review the data for results. The results help in identifying the wastes and defects for the process. It also gives an in depth root cause analysis of the problem.

Improve Phase:

This phase gives the solution on fixing the problem. If the project team is satisfied with the results and the data, the team shall implement ideas while solving the problem. This will help in finding the end solution for our problem.

This will generate improvement ideas for the project.

Control Phase:

This phase is a smaller version for process management. The team finds the improvement process in application for the employees who work on the process. Thus this phase documents how the process is running and the parameters that need to be controlled for proper implementation of the project.

For Lean Six Sigma Training needs, Visit http://www.zarantech.com/course-list/sixsigma. Call 515-309-2098 or email [email protected].

99999999 (Toll Free)

99999999 (Toll Free)  +91 9999999

+91 9999999